|

My Canadian detuned Optimus was shooting reasonably well but never had the accuracy of my full power version. The full-power I detuned to 800fps and this detuned Canadian version I uptuned to 630fps. My review in the other sub-forum section explains the details on the two rifles.

After pushing a bunch of pellets through the detuned Optimus, I discovered that the bore was far from acceptable. It started off tight at the breach and then got tighter right after the block. About 3" from the muzzle it got loose. I tried polishing with JSB Paste mixed with jeweler's rouge but that wasn't enough. A fresh crown didn't seem to help either.

It took some lengthy thought but I decided to sand the bore as per directions from chevota. Sanding by hand seemed like a radical approach to fixing a bad barrel. I ended up splicing a couple of bamboo skewers together to give a 2 foot rod with 1/8" thickness. This worked out well when I taped and wrapped a 4" wide strip of 320 grit. The constricted areas in the barrel were easy to find while sanding. I focused on them until they relaxed. Then I moved to 600 grit and finally some JSB Paste on a patched q-tip that I threaded into a .177cal cleaning rod. I touched up the crown with a brass screw and a JB/rouge blend. The breach seal was changed to a fitted 109 Viton o-ring that I thinned a bit from the back side (sanded).

All accuracy testing was done with a Leapers 3-9AO adjusted to 9X. I shot all groups from the same shooting area and from the same rest combo. I did not remove the barrel or touch the block washers, breach plunger, or trigger. All I did was sand the bore and lightly touch up the crown that already looked great from a previous crown polishing.

--- 50 yards – 5 shot groups ---August 2017

H&N Sport - 2.78, 2.15, 2.54, 1.61, 1.90, 2.38 -- Ave = 2.23" ctc

JSB Exact - 2.49, 2.12, 2.98, 2.45, 2.96, 2.22 -- Ave = 2.54" ctc

The following groups were from yesterday. Post barrel sanding. All groups were recorded and not cherry picked from a big batch.

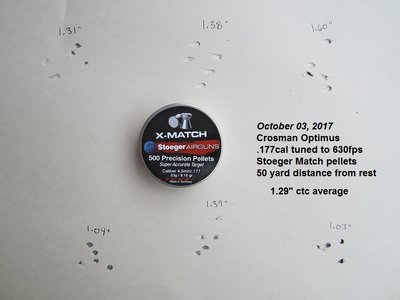

--- 50 yards – 5 shot groups --- October 3, 2017

Stoeger Match – 1.31, 1.38, 1.60, 1.04, 1.39, 1.03 –- Ave = 1.29” ctc

JSB Exact – 1.91, 2.20, 1.93, 2.02, 1.66, 1.13” -- Ave = 1.81" ctc

My .177cal 800fps Optimus was always more accurate than the milder version. Here is what the 800fps version did this summer at 50 yards. Both rifles now seem to shoot about the same accuracy at 50 yards. I hope they stay shooting this well!

--- 50 yards - 5 shot groups --- July 2017

JSB Exact - 1.47, 1.50, 1.56, 1.18, 1.15, 1.56, 0.73, 1.09, 1.11, 1.50, 1.49, 1.25, 1.05, 1.46, 1.39, 1.56, 1.07, 1.34, 1.17, 1.69 – Ave = 1.32" ctc

| Attachments: |

Opt600at50 004b.jpg [ 160.45 KiB | Viewed 2127 times ]

|

Opt600at50 001b.jpg [ 307.29 KiB | Viewed 2127 times ]

|

|