I've fixed quite a few of these, and trust me there have been some bad ones, but this one was a heck of a nightmare....and I knew right from the start that something was odd/weird just by looking at the end cap.....

pic's of end cap...a stock looking 600 end cap is on the right

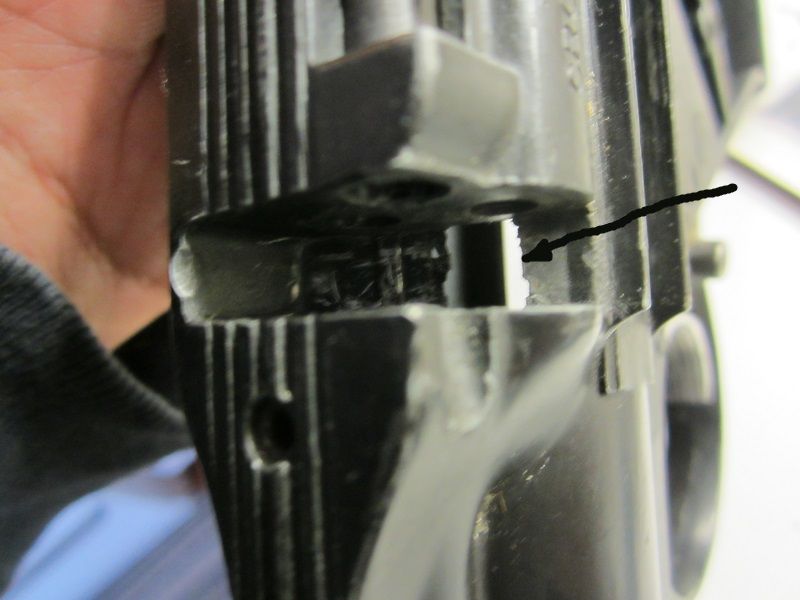

so I start to dissemble the 600 everything is going pretty smooth until I pull the main tube out, there are two small screw type

pins that hold the valve in place from moving, well looks like someone forced them back on and filed them down...so I had to macgyver something to get them out without causing any further damage to this thing

finally got the pins out now to remove the valve...anyone that's worked on one of these knows the valve has an o-ring that sits between the two halves of the valve that prevent the CO2 from escaping around the valve but also secures the valve from just sliding

out once the pins have been removed....normally you unscrew the front section of the valve, loosening the tension on the o-ring and then slide the valve out the front of the tube...well that's out of the question due to this mod that who knows how many owners before had put this thing in....

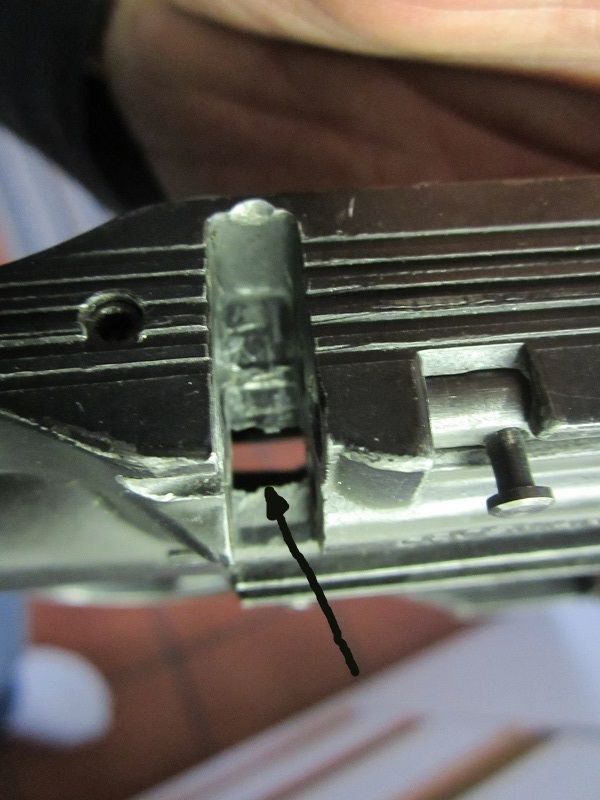

managed to get the valve out (forced out) and found this thing siting in front of the valve don't even know what its called...never seen one like it before, some kind of piercing mechanism

don't know why someone would go through all this trouble to put in this piercing gizmo and not just get an end cap

here is the valve by its self looks like an older version the newer style has an aluminum back section as appose to the brass.

you can clearly see the o-ring has gone hard on it and you can see the front section were you would unscrew it to remove it from

the tube easer..

after remove the valve halves to inspect the valve stem seal I noticed the valve seat had a nick on it this will prevent the valve

stem from seating properly and will cause leaking....so I had to polish it flat again...also the valve stem was bent as well, it just keeps getting better

the hammer has an o-ring on the inside this rides along the back half of the valve assembly it was all pitted and rough this will also cause leaks and will not allow the 600 to self cock...

after some polishing, much better surface for an o-ring

here is the best and most shocking part the breach area was completely worn out to the point that you could see right through it

this is not a big deal because the tube rides along the inside but I've never see anything worn out like this before....

one more....you can see my kitchen tiles through that hole lol...

being one to never give up on something, its all back together and working fine like it should be....